- Business cards

Need help?

Look around first, for inspiration and ideas

- Vouchers Gift cards

- Certificates Diplomas

- Presentation folders Ring binders

- Company stationery

- Tags Hang tags

- Stickers Tamper proof labels

- Flyers Posters

- Invitations

- Writing Pads Notepads

- Stamps

- Postcards Carnets

- CD DVD discs and sleeves

- Samples

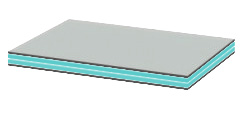

Layering

![]() Layering in the premium products sector

Layering in the premium products sector

Laminating can produce very thick business cards, cards or invitations. It allows several different or the same layers of paper to be combined. Papers of different textures and weights can be combined. The result is a thicker material that, by its sheer volume, enhances and emphasises the prestige of the owner. Laminating can make the laminated material different on one side than on the other. In fact, there can be one (or more) layers of paper in between the two outer layers. Different thicknesses of paper layers can be used for lamination. Very interesting effects can be achieved by using thin papers on the outside and thick papers on the inside. The result is a "sandwich" with a thick filling.

Sandwiched card of 4 layers. Thin layers of paper on the outside and thick layers on the inside

Coloured edges

With layering we can replace edge coloring. The effect of colored edges obtained by sandwiching can be better than the actual dyeing with paint. Coloring the edges with paint depending on the quality of workmanship can be very unstable. The edges of the business card are most exposed to chafing. Nothing will happen when layering. There is paper there that is dyed in its mass and will not rub.

More layers - thicker product

2 layers

Paper layering - 2 layers glued

If different papers are used then you get, for example, a business card with different surfaces on the front and back. They can be layers of the same type of paper with different colours or completely different.

3 layers

Paper layering - 3 layers glued

We then obtain a substrate of approx. 900g/m2. A so-called 'sandwich' effect can then be achieved, where the middle layer has a different colour to the top layers. The middle layer can of course only be seen from the edge.

4 layers

Paper layering - 4 layers glued

The material is then very thick. The overall weight is approximately 1200g/m2. The middle layers similarly to the 3-layer version can be used to create a "sandwich" effect but with a much thicker "filling" 🙂 .

Layering in the packaging industry

In the packaging industry, layering is the process of wrapping with a thin finishing layer of paper. It is rather called lamination. Most often used for wrapping thick cardboard or cardboard boxes. However, not only. Rigid book covers are also layered.

Layering and Multiloft

You have probably heard about "Multiloft" on the occasion of multilayered products, and in particular about Multiloft business cards. This technique is invented and patented by the US company Mohawk. We explain below what this technique is and what are the main differences between real layering and multiloft.

Layering is a physical glue

Multilayered business cards consisting of 4 layers of paper.

During layering, the combined layers are joined in a very durable way. With physical glue on the entire surface. It is a relatively long process compared to Multiloft because it requires the glue to dry. However, this is the most durable way possible to combine paper. It is impossible to separate the individual layers without destroying them. There are no restrictions on the use of any paper stock. You can combine thin papers with thick papers, metallized with traditional or even cotton. You can choose any color sets, which is impossible with Multiloft.

Multiloft - what is it?

In the "multiloft" technique, paper layers are combined differently. Just the slicer itself (guillotine). The joint occurs when the finished product is cut. Special patented surface properties of individual layers are already coated in the factory with special contact adhesive. They are only 3 layers - two external (white or cream) and one colored dyed in the mass that is between them. Under the pressure of the slicing knife, the surfaces of the touching layers are joined, which lie on each other in the right order. After joining (junction at a pressure of at least 3 kg/cm2 they form a kind of "colorful sandwich". As a result, the layers of paper are joined together, but only at the edges. The extent of this connection is from 1 to about 5 mm depending on the pressure force of the pressure beam, sharpness and geometry of the guillotine knife. Paradoxically, the more worn and blunt the knife, the better "stuck" multiloft.2) form a kind of 'coloured sandwich'. In effect, the paper layers are joined together, but only at the edges. The thickness of this joint ranges from 1 to about 5 mm, depending on the pressure of the pressure bar, the sharpness and the geometry of the guillotine knife. Paradoxically, the more worn and dull the knife, the better the 'glued' multiloft.

Restrictions on the use of Multiloft

Because it is a patented technique and is subject to licensing, production and distribution take place under strict control. There is no possibility of any paper selection. Recipients rely solely on the paper offered by the manufacturer himself. The same applies to insert colors. There are a limited number of them. Multiloft is very effective in production, because it allows you to bypass the gluing process and very quickly return the finished product to the customer. However, it has often happened that multiloft products have stratified. Not bad when it happened at the stage of quality control. It is worse when it happens after the sale to the customer or even after handing over, for example, a business card to the contractor. Sometimes a slight tension is enough to let the layers part on some edge. It is not difficult to imagine contractor's reaction with a "multiloft" business card might look like, which will delaminate in his hands.