- Business cards

Need help?

Look around first, for inspiration and ideas

- Vouchers Gift cards

- Certificates Diplomas

- Presentation folders Ring binders

- Company stationery

- Tags Hang tags

- Stickers Tamper proof labels

- Flyers Posters

- Invitations

- Writing Pads Notepads

- Stamps

- Postcards Carnets

- CD DVD discs and sleeves

- Samples

Embossing (convex)

Embossing process

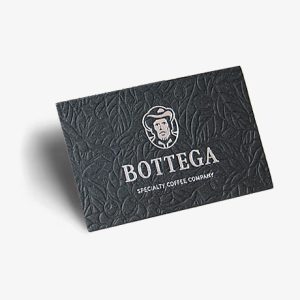

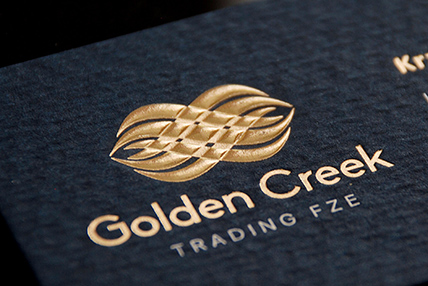

Business cards on decorative paper with hot-stamping and embossing

Convex embossing (embossing) is one of the key techniques used for print enhancement. It involves physically deforming a substrate so that convex elements are formed on it. This technique uses dies in which a concave pattern is engraved. In contrast to letterpress, where the embossed material lies on a hard flat surface, convex embossing uses a pressure element in the form of a flexible material, e.g. rubber, or a countermatrix (patrix). The patrix is like the negative of the die. It bears the same pattern, only inverted and convex. After embossing, the result is an impressed pattern on the material that is convex on one side and concave on the other. Embossing can be used to emphasise a logo, ornament, text, graphic sign or any shape. The best relief effects are achieved with the simplest possible shapes. The accentuated spatial element is clearly perceptible to the touch and more visible. Embossed elements are, for example, credit cards with embossed numbers, medicine packages with embossed text in Braille, business cards, but also cosmetics packaging, tags, clothing items, loyalty cards, etc.

Types of embossing

Three-dimensional (3D). This type of embossing requires very careful preparation of the pattern and a thorough preparation of the die. Three-dimensional embossing is similar to bas-relief in its effect. It is actually only used for graphics and vectorized photographs. Ordinary embossed lettering, for example, does not make sense using the 3d technique. 3D embossing dies are only made by CNC engraving.

Pseudo 3D. The 3D relief embossing effect can be achieved using chemically etched dies. Due to the physico-chemical properties, a die immersed in a chemical solution will be etched deeper where the pattern elements are larger and shallower where the elements are fine. By using chemical etching and proper preparation of the design, it is possible to give the impression of a three-dimensional pattern.

Single storey (2.5 D). The most common embossing, where all elements are embossed to an identical height.

Blindprint - blind embossing

Finishing can occur on both printed and unprinted areas. One variation of both embossing and letterpress is blindprint, or so-called 'blind printing'. The embossed lettering or graphics are located where there is no print. The embossing in this technique does not have to be done as precisely as in traditional embossing, as it does not have to coincide with the print.

Convex vs. concave. Embossing vs. Letterpress

Convex embossing is more widely used because it can be carried out on many materials: paper, plastics and leather. These materials can even be very thin. For letterpress, on the other hand, the material must be thick enough so that the indentation is deep enough to be seen or felt. For more difficult materials, such as plastics or leather, the embossing is done with a heated embossing die so that the material retains its deformation. In the case of paper, this is not relevant.

Notes on embossing technique:

Concavity on the reverse. If the embossing is carried out on only one layer of paper, a concavity (depression) is visible on the reverse side. The visible concavity effect is avoided when later leyering is used, i.e. gluing two or more layers of paper together.