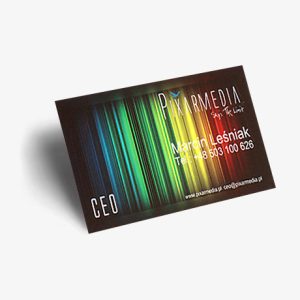

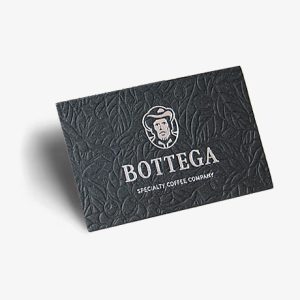

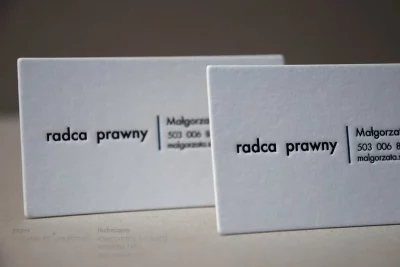

- Business cards

Need help?

Look around first, for inspiration and ideas

- Vouchers Gift cards

- Certificates Diplomas

- Presentation folders Ring binders

- Company stationery

- Tags Hang tags

- Stickers Tamper proof labels

- Flyers Posters

- Invitations

- Writing Pads Notepads

- Stamps

- Postcards Carnets

- CD DVD discs and sleeves

- Samples

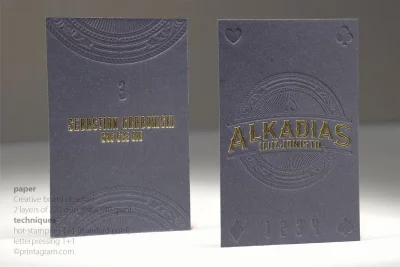

Letterpress (debossing)

Letterpress (debossing) it's Typography

Letterpress business cards on Wild white 450 gsm cotton paper.

Letterpress is a very old method. It is called 'typography'. Letterpress is an Anglo-Saxon name used mainly in the United States. It consists of imprinting fonts or other graphics prepared on convex stencils. When used on sufficiently thick materials, it leaves an imprinted pattern. It can be used to make concave embossing.

The term 'typography' has two meanings, which used to be one and the same before the invention of advanced printing techniques. It denotes both the relief printing technique (i.e. one in which the printing element, i.e. the matrix, is relief) and the structuring and arranging of texts in their visual dimension (the art of lettering).

Today's relevance of letterpress

Today, letterpress, understood as classic typography, has a different role. It is seen as a printing technique, but above all as a refinement technique. With the help of letterpress machines, very visible indentations can be produced in materials, and as a result - among other things - letterpress is now more often identified with the art of printing than with a technique for meeting industrial needs. Originally used exclusively for printing - it is now mostly used for intaglio embossing in thick paper. Using the same technical means, it is possible to reproduce designed graphics in such a way that both concave and convex embossing are created. Packaging with relief brand logos or relief promotional materials such as business cards or invitations are just a few examples of products that can be refined in this way.

The classic typographic technique is experiencing a second youth

Letterpress is popular despite the fact that it requires a lot of preparation and the use of outdated machinery. It is experiencing its second youth due to the many new papers that have become available and the renaissance of interest in the 'vintage' style. The most interesting of the new materials is the cotton paper we are using at the moment, which has a very interesting feel and is 'plump' enough to easily imprint different patterns on it. On such a "raw" textured surface, a beautiful effect of space is achieved, a three-dimensionality that is not perceptible at the graphic design stage, but only when the relief is physically carried out. The effects of letterpress can be seen in the subtle refraction of light on the edges of the relief patterns in the recesses made. Letterpress, despite its often minimalist designs, is seen as a very elegant finishing technique. A well-chosen printing substrate, its texture and colour, together with smooth debossed elements, give products effects that are impossible to design and visualise on a computer. Visualisations (mockups) often only give a substitute for what is achieved in reality.

Technical notes for letterpress

Letterpress can be made on both sides of the same material, but care must be taken to ensure that there are no other intaglio embossings on the reverse side at the point of pressing. They should be designed in such a way that the debossing on one side is "overlapped" by the debossing on the reverse side.