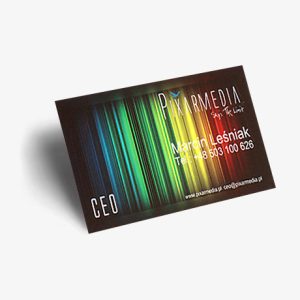

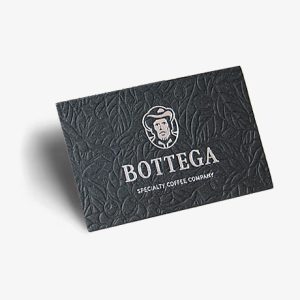

- Business cards

Need help?

Look around first, for inspiration and ideas

- Vouchers Gift cards

- Certificates Diplomas

- Presentation folders Ring binders

- Company stationery

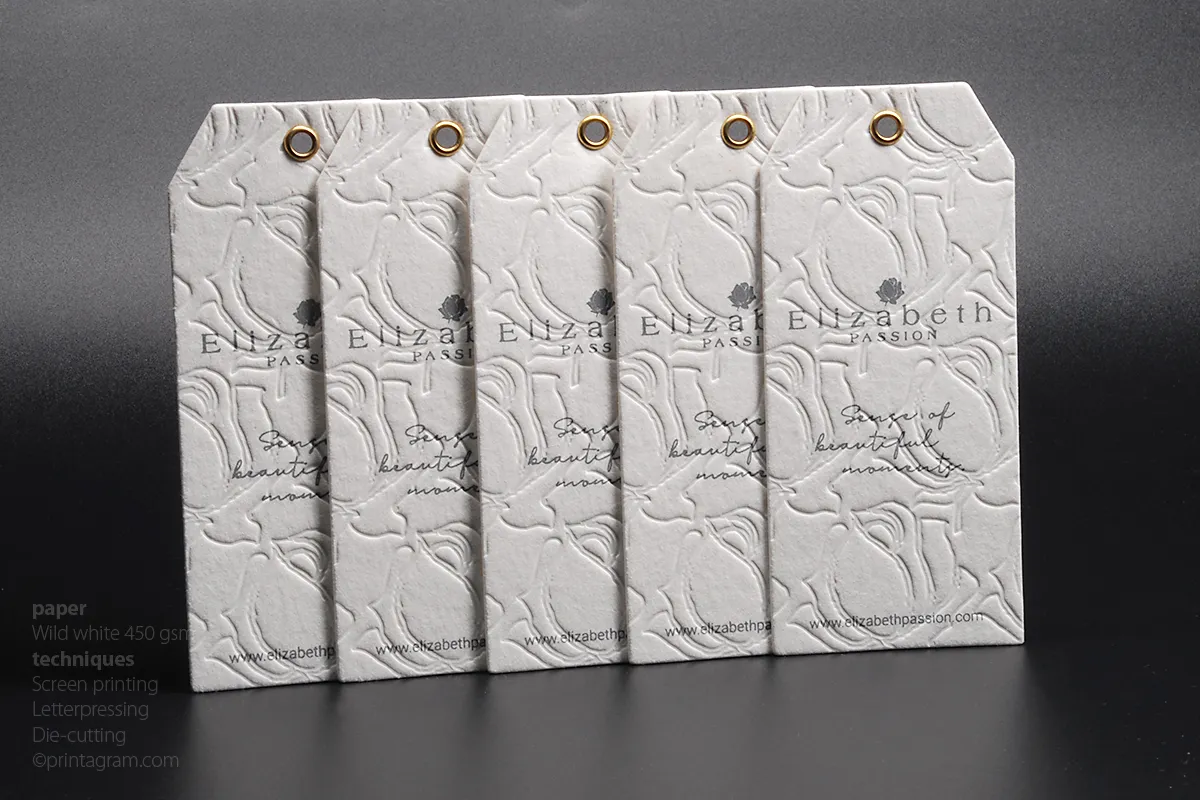

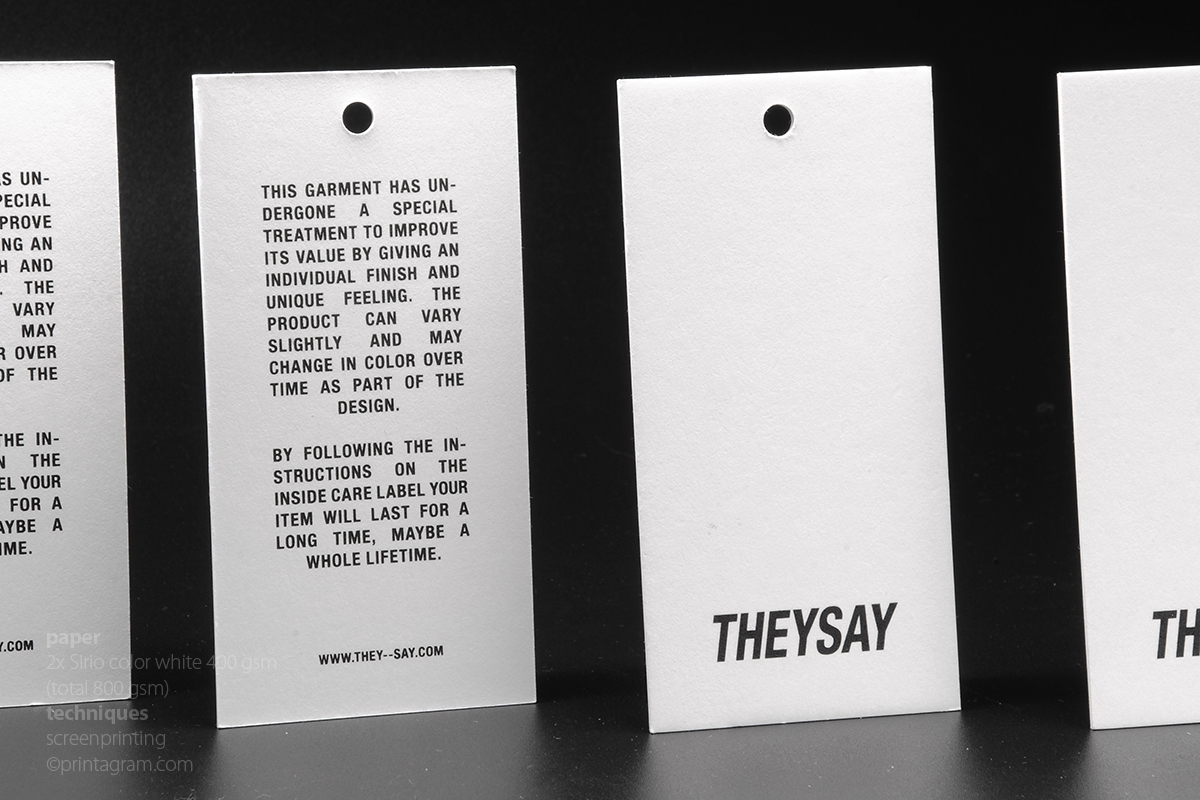

- Tags Hang tags

- Stickers Tamper proof labels

- Flyers Posters

- Invitations

- Writing Pads Notepads

- Stamps

- Postcards Carnets

- CD DVD discs and sleeves

- Samples

Printing and finishing

Metallic 3D

3D relief foiling

This technique is the matrix-free application of metallised film. Using very strong pressure rollers, the metallised film is applied over the entire surface. However, it only adheres to those areas on the material where the so-called surface tension is appropriate.

The "poured" or "liquid gold" effect is achieved by selective coating with a special convex material. The thickness of such a layer depends on several factors and ranges from 50 - 150 microns. It is then covered with a metallised film as described above. The metallised foil only adheres to the special convex material, giving a beautiful effect of a thick convex layer of gold, silver or another colour.

Hot stamping

Hot-stamping requires a die, hot-stamping foil and a pressure-generating device (press). The die is usually made of metal or a metal alloy. The idea is that the process is carried out at a temperature of around 120-200 degrees. The matrix must be able to withstand considerable loads in the order of several tens of kg per cm2 and at the same time conduct heat well.

The process involves stamping the design using a hot metal die. The pressing is done through a hot-stamping foil. The foil, or rather the active layer of the foil, adheres firmly to the substrate at the pressure point of the die and sticks to it.

Layering

Thanks to layering we can get very thick business cards, passes or invitations. It allows to combine several different or the same layers of paper. You can combine paper with different textures and weights. As a result, we get thicker material, which by its volume enhances and emphasizes the prestige of the owner.

Layering can make the product different on one side than on the other. Bah! there may be one (or more) between two outer layers of paper in the middle between them. You can use different thickness of paper layers for layering. Very interesting effects are obtained by using thin papers on the outside and thick papers on the inside. The effect is a "sandwich" with a thick filling.

UV selective varnishing

When applied to a matt surface, selected elements such as logos, graphics, names etc. are glossy and nicely highlighted. It is also possible to create new graphic elements that are visible from the right angle to enrich the design. In this way, lacquered backgrounds, "watermarks", patterns, textures, etc. can be used.

*Note.

It is not always possible to achieve good results. Particularly when UV varnish is applied to very absorbent and "rough" papers without pre-printing, it can happen that the varnish has time to absorb into the paper before it cures, resulting in a non-uniformly glossy surface. (e.g. Wild, Cotton, etc.)

Embossing (convex)

Embossing is one of the key techniques used for print enhancement. It involves physically deforming a substrate so that convex elements are formed on it. This technique uses dies in which a concave pattern is engraved. Unlike letterpress, where the embossed material lies on a hard flat surface, relief embossing uses a pressure element in the form of a flexible material, such as rubber, or a countermatrix (patrix).

Letterpress / Typography

Letterpress is a very old method. It is called 'typography'. Letterpress is an Anglo-Saxon name used mainly in the United States. It consists of imprinting fonts or other graphics prepared on convex stencils. When used on sufficiently thick materials, it leaves an imprinted pattern. It can be used to make concave embossing.

The term 'typography' has two meanings, which used to be one and the same before the invention of advanced printing techniques. It denotes both the relief printing technique (i.e. one in which the printing element, i.e. the matrix, is relief) and the structuring and arranging of texts in their visual dimension (the art of lettering).

Golden edges

The gilded edges are achieved by covering the edges with a metallised foil. It would seem that the foil for edge gilding is the same as for hot-stamping. However, this is not always the case. The edge colouring foil must have very good adhesion parmeters. It is also applied in a different way. The foil must adhere to the edge very well in order to avoid the effect of its fragments peeling off.

Currently, only gold, silver and copper colours are possible. The best visual effects are when the business cards or passes are thick - composed of two or more layers of paper.